How customer-led strategy unlocked a $150M market opportunity

Legislative Tailwinds

In October 2020, Maryland became the first U.S. state to enact a ban on polystyrene foam. Over the next few years, states like California, New York, and Colorado followed. As foam bans rolled out across the country, a leading disposable tableware manufacturer recognized a strategic inflection point.

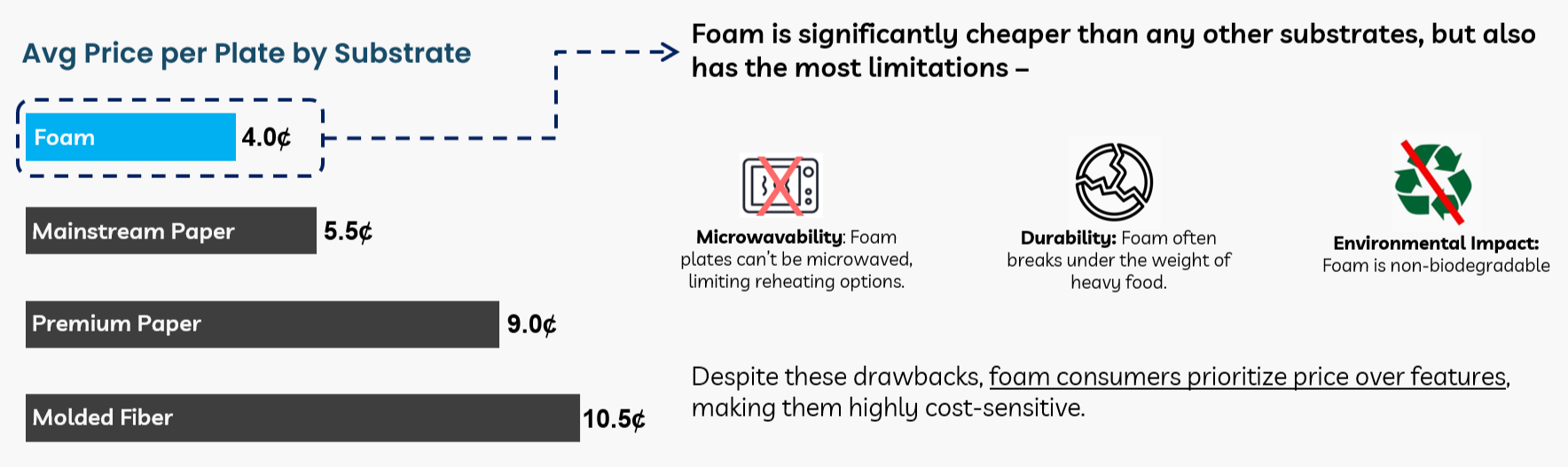

The U.S. market for foam plates was estimated at ~$450–500M. Capturing even a fraction of that displaced demand represented a significant white space. But foam plate consumers are among the most cost-sensitive in the category, thus any solution would need to be cheap, scalable, and non-cannibalizing to the company’s legacy premium product lines.

The Challenge

The product team was tasked with a deceptively simple brief:

Build a low-cost plate that foam buyers would accept without degrading brand equity or profitability.

The engineering teams iterated for months - cutting board weight, redesigning tooling, tweaking shapes. Dozens of prototypes were tested internally for durability and grease resistance, then shown to focus groups.

Results were tepid. The team went back to the drawing board. Again. And again. A year passed with little traction.

Rethinking the Approach

I joined the innovation and strategy team during this period and immediately saw the flaw:

We were trying to validate solutions without first understanding the consumer's mental model.

The team shifted toward a customer-centric design strategy. We conducted structured interviews and value-driver analyses to better understand not just what foam users were buying, but why. We learned that although price was critical, customers were making nuanced tradeoffs around perceived strength, versatility, and “good enough” durability.

These insights became inputs for a series of facilitated design sprints, where we invited cross-functional teams to reimagine the product based on customer jobs, friction points, and overlooked value signals.

The Breakthrough

One concept stood out:

A redesigned plate with steeper side angles and more depth - engineered to look and feel sturdier while still using the lighter weight material.

This solved multiple problems:

Perceived durability improved due to angular reinforcement

Board weight stayed low, preserving margins

Usage occasions expanded (e.g., pastas, salads, cereal), reframing it as a versatile option—not just a budget one

We weren't just mimicking foam. We were solving a broader customer problem with a smarter, more functional product.

The Outcome

Through iterative concept testing, the final design delivered:

· 90%+ purchase intent in target consumer segments

· Strong interest from national retailers, with discussions around both branded and private label placements

· Internal forecasts estimated a $150M+ opportunity, driven by projected volume across multiple channels

· Increased Household penetration of ~5 Million (~11%HH Penetration growth)

And perhaps most importantly, internal confidence that innovation could be faster, cheaper, and more aligned with real customer needs than traditional R&D cycles.